High-performance solar road studs: a cost-effective buying guide

With the enhancement of road traffic safety requirements, solar road studs have become an important safety facility for all types of roads by virtue of the advantages of active illumination and strong warning. However, the quality of products on the market varies, the price span, how to accurately select the appropriate scene, cost-effective products, become the core demand of the purchaser. In this paper, we disassemble the key points from the core cognition, purchase dimensions, scene adaptation, etc., to provide comprehensive guidelines for cost-effective purchase.

Solar road studs core knowledge

Working principle

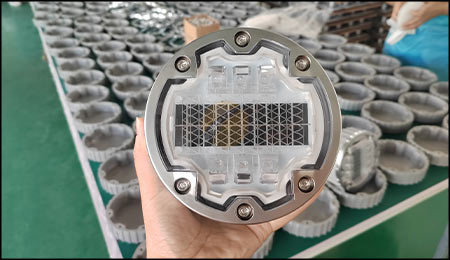

The working logic of solar road studs is very simple, the core is through the four major components operating in tandem to realize the independent light-emitting. Solar panels absorb sunlight during the day, light energy into electrical energy; energy storage device is responsible for storing the converted electrical energy, to provide power for the night light. LED light-emitting components in the night will be converted into light energy to achieve active light. The controller intelligently regulates the charging and discharging process to avoid overcharging and over-discharging damage to the components, and controls the LED light-emitting mode and brightness.

Different types are suitable for different scenarios

Solar road studs are categorized in many ways, of which the most practical value is categorized according to the installation location and energy storage components, and the different types of suitable scenarios and cost differences are obvious, as shown in the table below:

|

Classification Dimension |

Type |

Key Features |

Suitable Scenarios |

Cost Level |

|

By Installation Position |

In-ground |

Flush with road surface; does not affect vehicle movement; strong load-bearing capability |

Highways, urban main roads |

Medium–High |

|

Raised |

Protrudes above road surface; wide lighting angle; easy installation |

Rural roads, temporary construction sections, mountainous roads |

Medium–Low |

|

|

By Energy Storage Type |

Capacitor-based |

Fast charging and discharging; long lifespan; limited energy storage and poor endurance during cloudy or rainy days |

Short-term temporary roads, high-sunlight regions |

Low |

|

Battery-based |

Large energy storage capacity; strong endurance in cloudy and rainy conditions; wide application range |

Long-term road applications of all types |

Medium |

Solar road stud core advantages

Compared with the traditional ordinary reflective Road stud, the core advantages of solar Road stud are reflected in the active light-emitting ability, the specific differences are listed below:

|

Comparison Dimension |

Solar Road Studs |

Conventional Reflective Road Studs |

|

Lighting Method |

Active illumination; no reliance on external light sources |

Passive reflection; requires vehicle headlights |

|

Brightness Level |

≥2000 mcd, high brightness |

Low brightness; highly dependent on headlight intensity |

|

Performance in Rain & Fog |

Strong penetration; remains visible in heavy fog and rain |

Weak performance; warning effect significantly reduced in rain or fog |

|

Visibility Distance |

Long range, up to several hundred meters |

Short range, typically less than 100 meters |

|

Suitable Applications |

Unlit roads, fog-prone areas, mountainous roads, hazardous sections |

Well-lit roads with good driving conditions |

Cost-effective solar studs 6 dimensions

Compressive performance

Solar studs long-term exposure to vehicle crushing, compressive performance directly determines its service life and safety, compressive substandard shell rupture, damage to the internal components and other issues are very likely to occur. Procurement should focus on whether the product has authoritative compression test report, while avoiding hollow structure, with the foot of the nail easy to separate styles. For an economical option, prioritize PC bulletproof material panels with a one-piece reinforced body shell. This road-resistant structure is stable and can withstand frequent vehicle traffic.

Sealed waterproof

Road environment is complex, rain, water, dust easy to invade the stud internal short-circuit failure, resulting in product failure, so sealed waterproof is the core of the solar stud protection. When choosing, you need to recognize the products with waterproof grade ≥ IP67, which means that they can be immersed in 1 meter deep water for 30 minutes without damage, and at the same time, prioritize the products with separated design and strong adhesive process, which have more stable sealing performance.

Matching energy storage and power supply

The energy storage and power supply system of solar studs determines the endurance, especially in continuous rainy weather can be normal light is the key, the core needs to pay attention to the two components of solar panels and batteries. Solar panels prioritize the selection of photoelectric conversion rate ≥ 14% of monocrystalline silicon, suitable for most of the normal sunshine areas.

Low sunlight areas can choose bicrystalline silicon with better low-light performance. Battery priority 1200mAh + lithium batteries, charging and discharging 1000 times after the capacity is still ≥ 79%, to avoid capacitive products, to ensure that charging 8 hours can be continuous light more than 72 hours.

Brightness and warning effect

Solar road studs brightness directly affects the warning effect, to meet the standards of the Ministry of Transportation ≥ 2000MCD, under this premise, the dynamic flashing models warning stronger than the normal light models, more suitable for accident-prone road. Cost-effective solar road studs do not need to blindly chase excessive high brightness, the higher the brightness, the higher the energy consumption and price, should be matched according to need. Highway, mountainous fog area can choose high brightness models, rural highways, ordinary side roads can choose conventional brightness models, both to meet the warning needs and cost savings.

Environmental adaptability

Different regions have large differences in climate, high temperature, low temperature, high humidity will affect the service life of solar road studs, when purchasing the need to pay attention to environmental adaptation parameters, give priority to the selection of operating temperature - 20 ℃ ~ 85 ℃, can withstand 45 ℃ 98% humidity 48 hours of stable work of the product. Selection of solar road nails need to be targeted to adapt to the regional climate. Cold winter, choose low-temperature range of strong lithium battery models, high temperature and high humidity in summer, choose high-temperature lines, sealing performance better products.

Stability

Solar road studs stability is directly related to the late maintenance costs, poor stability of the product is prone to failure, frequent replacement and maintenance will increase the cost of use. Selection focus on three points, line selection design is simple, solid solder joints, to avoid poor contact. Choose products equipped with authentic reflective mold core, 10 meters flashlight test can be clearly reflected. Priority selection warranty ≥ 3 years of the brand, the quality of such products is more secure, can reduce the late replacement costs.

Choose solar road studs according to the scene

Highway / mountain fog area

Highway, mountain fog area scenarios, fast vehicle speed, rain and fog weather, the solar road studs compression resistance, brightness and endurance requirements are extremely high. It is recommended to give priority to the protruding one-piece model with high compression resistance (≥10 tons) + high brightness (≥2000MCD) + long endurance, paired with monocrystalline silicon solar panels and high-capacity lithium batteries to ensure that it can withstand high-speed crushing and work stably in continuous rainy weather.

Countryside / rural highway

Rural highway procurement budget is usually limited, and some areas have poor lighting conditions, the core of the selection is “economic and practical”. It is recommended to choose bicrystalline silicon photovoltaic panels + regular brightness protruding battery model road studs, avoiding remote monitoring and other high-priced smart features. Bicrystalline silicon photovoltaic panels are adapted to low sunlight environments, and regular brightness can meet the needs of rural highway warning, which is the most cost-effective choice in this scenario.

Municipal roads / construction temporary sections

Municipal roads have high pedestrian and vehicular traffic, and construction temporary sections need to be deployed and moved frequently, which requires high flexibility and wear resistance of the product. It is recommended to choose a movable protruding product with an easy-to-clean PC panel to facilitate daily maintenance and mobile deployment. At the same time, we need to ensure that the product has good pressure resistance and sealing performance, in order to adapt to the complex use of municipal roads.

Tunnel entrance / bend

Tunnel entrances are characterized by sudden changes in light, and sight lines are obstructed at bends, so solar road studs are required to provide stronger warning and light penetration. We recommend the Dynamic Flashing High Brightness LED model with sealed waterproof upgrade design. Dynamic flashing mode can quickly attract the attention of drivers, high brightness and strong sealing performance can ensure stable work in the tunnel under the humid environment, to protect driving safety.

Guide to avoiding the pit

Reject low-priced “three-nos” products

Some of the low-priced solar road studs on the market belong to the “three-nos” products, with no compression test report, no waterproof grade marking, and no warranty commitment. These products are mostly low-quality materials, compressive and waterproof performance does not meet the standards, the service life is extremely short. Purchase of such products is not only the late maintenance costs are extremely high, but also may cause safety accidents, so when purchasing must require businesses to provide authoritative test reports and warranty commitments, and resolutely reject the “three no” products.

Wary of “pseudo-high configuration”

Some merchants in order to attract customers, will be labeled false high parameters, such as exaggerated solar energy conversion rate, misrepresentation of the battery capacity, etc., the actual product does not have the corresponding performance. Tips for avoiding pitfalls is to ask merchants to provide parameter testing video or third-party test reports to verify the authenticity of the parameters. At the same time, you can intuitively determine the product performance through sample testing, such as testing the brightness, sealing waterproof and other key indicators, to avoid being misled by false propaganda.

Do not choose structural defects in the product

With nail foot separation structure, hollow shell, sealant cheap solar road studs, there are obvious structural defects, compressive and sealing is difficult to guarantee, easy to damage, water ingress and other problems in use. Procurement needs to carefully observe the product structure, give priority to one-piece molding shell, PC bulletproof material panel products, while checking whether the sealant is uniform and full, from the structure to avoid quality risks.

Money-saving tips

Want to enhance the procurement of cost-effective, bulk purchases, give priority to the choice of stud manufacturers direct supply channels, reduce intermediate links can significantly reduce the procurement cost. At the same time to focus on the core functions, without blindly pursuing additional intelligent features, for most road scenes, “pressure + waterproof + endurance + brightness up to standard” of the basic configuration has been able to meet the needs of the use of additional features tend to significantly increase the price, cost-effective is not high.

The core of the cost-effective purchase of solar road nails lies in the “scene adaptation + core performance to meet the standard”, avoiding the trap of three products and pseudo-high configuration, focusing on pressure resistance, waterproofing, endurance and other key indicators, combined with the optimization of procurement channels, you can achieve a balance between quality and cost. Reasonable selection of solar road studs can not only enhance the road warning effect, to protect the safety of passage, but also reduce long-term maintenance costs, help the efficient landing of road safety facilities.